Welcome to the True Temperature Control Manual, your comprehensive guide to understanding and optimizing temperature control systems․ This manual covers installation, operation, and maintenance, ensuring efficient performance․ Designed for user-friendly navigation, it provides clear instructions for achieving precise temperature regulation in refrigeration systems, helping you maximize efficiency and extend equipment lifespan․ Explore the detailed sections to master your True refrigeration unit’s temperature control capabilities․

1․1 Purpose of the Manual

This manual serves as a comprehensive guide to understanding and optimizing True temperature control systems․ Its primary purpose is to provide detailed instructions for installation, operation, and maintenance, ensuring efficient and precise temperature regulation․ Designed to be user-friendly, the manual offers clear, concise language to help users master their refrigeration units’ temperature control capabilities․ By following the guidelines, users can achieve optimal performance, extend equipment lifespan, and maintain consistent thermal conditions in their applications․

1․2 Importance of Temperature Control in Refrigeration

Precise temperature control is crucial for maintaining product quality, safety, and energy efficiency in refrigeration systems․ Proper regulation prevents temperature fluctuations, which can lead to food spoilage, equipment damage, and increased energy costs․ The True temperature control manual emphasizes the role of accurate temperature management in ensuring optimal performance, reducing maintenance needs, and prolonging the lifespan of refrigeration units․ By adhering to the manual’s guidelines, users can achieve consistent thermal conditions, safeguarding their products and operational efficiency․

Understanding Temperature Control Systems

Temperature control systems are essential for maintaining precise thermal conditions in refrigeration․ They include types like thermostats and sensors, ensuring efficient operation and optimal performance․ These systems automate temperature regulation, preventing fluctuations that could damage equipment or spoilage․ By understanding how these components work together, users can ensure consistent cooling, energy efficiency, and prolonged equipment lifespan․ This section explores the fundamentals of temperature control, helping you master its operation and benefits․

2․1 Types of Temperature Controls

Temperature control systems utilize various devices to regulate thermal conditions․ Common types include thermostats, which maintain set temperatures, and digital temperature controllers, offering precise adjustments․ Sensors, like platinum RTDs, detect temperature changes, ensuring accurate readings․ Automated systems integrate these components to optimize performance․ Understanding these types helps users select the right configuration for their refrigeration needs, ensuring efficiency and reliability․ Each type serves a specific function, contributing to overall system performance and temperature consistency․

2․2 General Sequence of Operation

The general sequence of operation in temperature control systems involves detecting temperature changes, processing data, and activating heating or cooling mechanisms․ Sensors, such as platinum RTDs, monitor the environment and send signals to the control unit․ The thermostat or controller interprets this data and compares it to the setpoint․ If deviations occur, the system initiates adjustments, such as compressors or fans, to restore balance․ Automation ensures precise and consistent temperature regulation, optimizing efficiency and maintaining desired conditions․ This sequence ensures smooth, reliable operation across various applications․

2․3 Role of the Thermostat in Temperature Regulation

The thermostat plays a crucial role in temperature regulation by maintaining preset conditions within a refrigeration system․ It acts as an intermediary, detecting temperature fluctuations and activating or deactivating heating or cooling mechanisms․ By continuously monitoring the environment, the thermostat ensures precise control, optimizing energy efficiency and preventing excessive system wear․ Its automated response guarantees consistent temperatures, safeguarding stored items and prolonging equipment lifespan․ This essential component is integral to the smooth operation of True refrigeration units, ensuring reliability and performance․

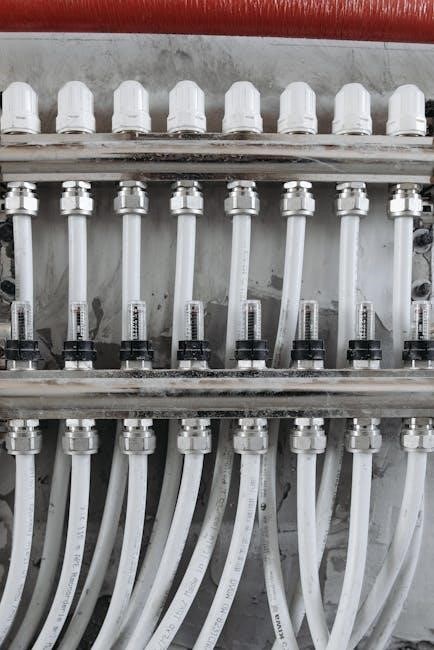

Components of the Temperature Control System

The temperature control system comprises essential components like sensors, thermostats, wiring, and controllers․ These elements work together to ensure precise temperature monitoring and regulation, maintaining optimal conditions efficiently․

3․1 Sensors and Their Functionality

Sensors are critical components that detect temperature changes and provide accurate readings to the control system․ They ensure precise monitoring and regulation of temperatures․ Types include thermocouples, thermistors, and RTD (Resistance Temperature Detectors), each offering unique accuracy and durability․ Proper sensor placement and calibration are vital for reliable performance․ They enable the system to respond to thermal variations, maintaining consistent conditions․ Regular maintenance ensures sensors function optimally, preventing errors and ensuring accurate temperature control․

3․2 Wiring and Connections

Proper wiring and connections are essential for ensuring accurate temperature control․ Use high-quality, insulated cables to prevent signal interference․ Connections should be secure and tightly fastened to avoid loose contacts․ Follow the wiring diagram provided in the manual to connect sensors, controllers, and other components correctly․ Improper wiring can lead to system malfunctions or inaccurate readings․ Always use appropriate connectors and tools to maintain reliability and safety․ Regularly inspect wiring for damage or wear to prevent potential issues․

3․3 Platinum RTD (Resistance Temperature Detector)

The Platinum RTD is a highly accurate sensor used to measure temperature changes by detecting variations in electrical resistance․ Known for stability and reliability, it provides precise readings over a wide temperature range․ Durable and resistant to corrosion, Platinum RTDs are ideal for refrigeration systems, ensuring consistent temperature control․ They are essential for maintaining optimal conditions, preserving the quality of stored items like food or medications․ Their accuracy is crucial for reliable operation in various applications․

Installation and Setup

Proper installation and setup of temperature control systems ensure precise temperature regulation․ This involves connecting sensors, configuring controllers, and testing the system to guarantee accurate performance and reliability․

4․1 Pre-Installation Checklist

A pre-installation checklist ensures all components are ready for proper setup․ Verify the system compatibility, check power supply requirements, and inspect sensors for damage․ Ensure the installation location is clean, dry, and accessible․ Confirm the availability of necessary tools and documentation․ Review safety guidelines and manufacturer specifications to avoid potential issues during installation․ This step is critical for a smooth and efficient setup process, minimizing downtime and ensuring optimal performance from the start․

4․2 Step-by-Step Installation Guide

Begin by powering off the system and ensuring all components are ready․ Connect the sensors to their respective ports, following the wiring diagram․ Mount the thermostat securely in an accessible location․ Carefully wire the system, ensuring all connections are tight and labeled․ Power on the system and test functionality․ Verify sensor readings and thermostat responses․ Complete the setup by configuring settings according to the manual․ Double-check all connections and ensure proper operation before finalizing the installation․

4․3 Initial Setup and Configuration

Access the control panel and navigate to the setup menu․ Set the desired temperature range and input sensor calibration values․ Review and confirm all parameters before saving․ Perform a system test to ensure accuracy and stability; Adjust settings as needed to achieve optimal performance․ Document the configuration for future reference and ensure all safety protocols are activated․ Allow the system to run a diagnostic cycle to verify functionality before full operation․

Calibration and Adjustment

Calibration ensures accuracy in temperature control․ Adjust parameters to match system requirements․ Test and document settings for consistency and future reference․ Ensure precise temperature regulation․

5․1 How to Calibrate the Temperature Control System

To calibrate the system, start by ensuring all components are powered and stable․ Use a precision thermometer to verify the sensor’s readings․ Adjust the system’s offset to match the reference temperature․ Perform calibration at multiple points within the operating range for accuracy․ Document the process and results for future reference․ Regular recalibration ensures long-term precision and reliability in temperature control operations․ Always follow the manufacturer’s specific calibration guidelines for optimal performance․

5․2 Adjusting the Temperature Range

To adjust the temperature range, access the control interface and select the desired range․ Use the adjustment tools to set upper and lower limits․ Ensure the system is cycled to test stability․ Fine-tune the range for precision, considering the application’s requirements․ Document the new settings for reference․ Regular adjustments may be needed based on environmental changes or specific operational needs․ Always refer to the manual for model-specific instructions to maintain accuracy and system performance effectively․

5․3 Fine-Tuning for Optimal Performance

Fine-tuning involves refining system settings for precise control․ Start by checking sensor accuracy and ensuring proper calibration․ Test the system’s response to temperature changes by observing recovery times․ Adjust sensitivity settings to minimize fluctuations․ Monitor stability over time and make incremental adjustments as needed․ Ensure all components are functioning within specified ranges․ Regularly review performance data to identify trends and optimize settings further․ This process ensures consistent and reliable temperature control, tailored to specific operational demands․

Automation in Temperature Control

Automation enhances precision and efficiency by integrating advanced controls, enabling real-time monitoring and adjustments; It streamlines operations, reduces human error, and ensures consistent temperature management across systems․

6․1 Automating Heating and Cooling Processes

Automation integrates sensors, controllers, and algorithms to precisely regulate heating and cooling․ It minimizes manual intervention, ensuring consistent temperature levels․ Advanced systems adapt to load changes, optimizing energy use and performance․ Automation also enables remote monitoring and control, reducing downtime․ By leveraging programmable logic controllers and IoT capabilities, systems achieve superior accuracy and scalability, making them ideal for industrial and commercial applications requiring precise temperature management․

6․2 Precision Temperature Control for Thermal Processes

Precision temperature control ensures accurate thermal management, crucial for maintaining consistent process outcomes․ Advanced systems utilize high-resolution sensors and dynamic control algorithms to regulate temperature fluctuations․ This level of control minimizes variability, enhances product quality, and optimizes energy efficiency․ Real-time monitoring and adaptive responses enable precise adjustments, ensuring compliance with strict process requirements․ Such systems are essential for industries requiring tight thermal control, such as pharmaceuticals, food processing, and advanced manufacturing․

6․3 Benefits of Automated Systems

Automated temperature control systems offer enhanced efficiency, consistency, and reliability․ They reduce manual intervention, minimizing human error and freeing staff for other tasks․ Automated systems optimize energy usage, lowering operational costs․ Remote monitoring and real-time adjustments ensure precise control, while data logging provides insights for process improvement․ Scalability and adaptability to varying demands make automated systems ideal for diverse applications, ensuring superior performance and compliance with regulatory standards․

Maintenance and Troubleshooting

Regular maintenance ensures system efficiency and reliability; Identify and address common issues promptly, such as sensor calibration, wiring faults, and software glitches, to prevent downtime․

7․1 Routine Maintenance Tasks

Regular maintenance is crucial for optimal performance․ Clean sensors, inspect wiring for damage, and verify thermostat settings․ Check system calibration annually and replace worn components․ Ensure proper insulation, test emergency shutdowns, and update software․ Maintain records of all maintenance activities to track system health and plan future servicing․ Address minor issues promptly to prevent major malfunctions, ensuring consistent and reliable temperature control․ Always follow manufacturer guidelines for specific tasks and safety protocols․

7․2 Common Issues and Solutions

Common issues include temperature fluctuations, sensor malfunctions, or faulty wiring․ For inaccurate readings, recalibrate sensors or replace them if damaged․ Address wiring issues by checking connections and insulations․ If the system fails to maintain setpoints, inspect the thermostat or controller for proper function․ Power fluctuations may require surge protectors or backups․ Always refer to troubleshooting guides for specific error codes․ Regularly updating software and ensuring proper insulation can prevent many issues․ Promptly addressing these problems ensures reliable operation․

7․3 Troubleshooting Techniques

Troubleshooting involves identifying and resolving system malfunctions systematically․ Start by reviewing error codes and system logs for clues․ Check sensor accuracy and wiring integrity․ Verify thermostat settings and ensure proper calibration․ Inspect components like relays and contactors for wear․ Use multimeters to test electrical connections and voltage levels․ Refer to the user manual for diagnostic procedures․ Isolate issues by testing individual components․ Document findings and implement corrective actions to restore optimal performance․ Always follow safety protocols during troubleshooting to avoid further damage or risks․

Safety Considerations

Ensure safe handling of electrical components, avoid extreme temperatures, and follow proper installation and maintenance procedures to minimize risks and guarantee reliable operation always․

8․1 Safety Precautions During Installation

Always disconnect power before starting installation to prevent electrical shocks․ Wear protective gear, including gloves and safety glasses, to minimize risks․ Use appropriate tools to avoid damaging components․ Ensure all connections are secure and properly insulated to prevent short circuits․ Verify the system’s compatibility with existing infrastructure to avoid safety hazards․ Follow the manufacturer’s guidelines strictly and double-check all wiring before powering up․ Keep the area well-ventilated and free from flammable materials․ Never proceed without proper training or supervision if unsure․

8․2 Operating the System Safely

Ensure only trained personnel operate the system to maintain safety standards․ Always follow the manufacturer’s operating guidelines and monitor temperature and pressure levels closely․ Regularly inspect hoses, connections, and valves for leaks or damage․ Keep emergency shutdown procedures readily accessible in case of malfunctions․ Avoid overheating by maintaining proper airflow and ventilation․ Use protective equipment when handling system components․ Never bypass safety features or alarms, and ensure all personnel are aware of potential hazards and emergency response protocols․

8․3 Emergency Shutdown Procedures

In case of system failure or hazardous conditions, initiate emergency shutdown immediately․ Press the emergency stop button to halt all operations․ Disconnect power supplies and isolate system components․ Ensure all personnel evacuate the area safely․ Activate ventilation systems if gas leaks are suspected․ Do not restart the system until authorized personnel confirm it is safe․ Document the incident and perform a thorough inspection before resuming operations․ Always prioritize safety to prevent potential hazards and ensure reliable system performance․

Accessing User Manuals and Resources

Access user manuals, technical guides, and support resources through the official website or authorized dealers․ Contact customer support for assistance or additional documentation needs online․

9․1 Where to Find Detailed User Manuals

Detailed user manuals for the True Temperature Control system are available on the official manufacturer’s website․ Visit the support section and search by model number or product name․ Authorized dealers also provide printed or digital copies upon request․ Additionally, registered users can access manuals through the customer support portal․ Ensure to verify the model number for accurate documentation․ Contact customer support if you encounter any issues accessing the manuals online or through authorized channels․

9․2 Technical Support and Service Resources

For technical assistance, contact the manufacturer’s support team via phone, email, or live chat․ Visit the official website for regional service centers and authorized repair partners․ Online resources include troubleshooting guides, FAQs, and downloadable repair manuals․ Registered users can access priority support through the customer portal․ Ensure to have your model number ready for faster assistance․ Regularly check the website for updated resources and service notifications to maintain optimal system performance;

9․3 Online Platforms for Additional Guidance

Online platforms offer extensive resources for mastering true temperature control․ Manufacturer websites provide video tutorials, webinars, and user forums․ Third-party sites like YouTube and specialized HVAC forums share practical tips and troubleshooting advice․ Joining industry-specific groups on LinkedIn or Reddit can connect you with experts and users for real-world insights․ Always verify information against official manuals to ensure accuracy and compatibility with your system․

Specific Models and Their Manuals

Explore detailed manuals for models like GDM, GDT, and BMG/TMG series, each tailored to specific temperature control needs and operational requirements․

10․1 GDM Series Refrigerator Manual

The GDM Series Refrigerator Manual provides comprehensive guidance for installing, operating, and maintaining GDM models․ It covers temperature control features, energy efficiency settings, and troubleshooting common issues․ Designed for commercial and industrial use, the manual includes detailed diagrams and step-by-step instructions for optimal performance․ Users can access it online or through authorized distributors․ This resource ensures seamless operation and extends the lifespan of the equipment, making it essential for technicians and end-users alike․

10․2 GDT Series Technical Manual

The GDT Series Technical Manual is tailored for advanced users, offering detailed technical specifications and operational insights․ It covers installation, calibration, and troubleshooting specific to GDT models․ The manual emphasizes precision temperature control, energy-saving features, and compliance with industry standards․ Intended for engineers and technicians, it provides in-depth wiring diagrams and advanced configuration options․ Available digitally, it ensures users can optimize performance and address technical challenges effectively, supporting long-term reliability and efficiency․

10․3 BMG/TMG Series Instructions

The BMG/TMG Series Instructions provide comprehensive guidance for installing, operating, and maintaining these advanced temperature control systems․ Designed for both new and experienced users, the manual covers setup procedures, calibration, and troubleshooting; It highlights energy-efficient features and safety protocols․ Detailed diagrams and step-by-step instructions ensure smooth operation․ The guide also includes maintenance schedules and tips for optimizing performance․ Available in multiple formats, it serves as an essential resource for users seeking to maximize the potential of their BMG/TMG systems effectively and safely․

Case Studies and Real-World Applications

This section highlights practical examples of temperature control systems in industries like food storage and pharmaceuticals, demonstrating improved efficiency and product quality through precise temperature management․

11․1 Successful Implementations of True Temperature Control

True temperature control has been successfully implemented in various industries, notably in food storage and medical refrigeration․ For instance, a leading food distributor reduced spoilage by 30% using precise temperature regulation․ Similarly, laboratories achieved consistent sample preservation through advanced control systems․ These implementations highlight how accurate temperature management enhances efficiency, product quality, and operational reliability, making it a cornerstone of modern industrial practices․

11․2 Industry-Specific Use Cases

True temperature control is widely applied across industries, each with unique requirements․ In pharmaceuticals, it ensures drug stability during storage․ The food industry uses it for precise refrigeration of perishables․ Laboratories rely on it for maintaining consistent conditions in experiments․ Manufacturing employs it for process control in chemical reactions or metal treatment․ Each sector benefits from tailored solutions, demonstrating the versatility and critical role of precise temperature management in achieving operational excellence and compliance with industry standards․

11․3 User Testimonials and Feedback

Users praise the True Temperature Control system for its reliability and precision․ Many highlight its ease of use and seamless integration into existing setups․ Feedback often mentions significant energy savings and reduced downtime․ Customers in food service appreciate consistent refrigeration, while laboratory users emphasize accurate temperature stability․ Overall, testimonials underscore the system’s ability to meet diverse needs effectively, fostering trust and satisfaction across various industries and applications․

True temperature control ensures precise, energy-efficient refrigeration, enhancing performance and safety․ Regular maintenance and updates are crucial for optimal functionality, making it a valuable long-term investment․

12․1 Summary of Key Points

Proper installation, calibration, and maintenance are essential for effective temperature control․ Sensors, thermostats, and automation play critical roles in achieving precise regulation․ Regular updates and checks ensure optimal performance, safety, and energy efficiency․ Understanding system components and following guidelines helps prevent issues․ Automated processes enhance accuracy and consistency, while routine maintenance extends equipment lifespan․ Adhering to safety protocols and accessing resources ensures smooth operation․ This manual provides a comprehensive guide for mastering true temperature control systems․

12․2 Final Tips for Optimal Temperature Control

Always monitor system performance to ensure accuracy and consistency․ Avoid extreme temperature fluctuations to maintain equipment integrity․ Regularly inspect sensors and wiring for damage or wear․ Use automation features to streamline operations and reduce manual errors․ Schedule routine maintenance to prevent unexpected downtime․ Keep the system clean and well-ventilated to enhance efficiency․ By following these tips, you can achieve precise temperature control, extend equipment lifespan, and ensure reliable performance in various applications․

12․3 Importance of Regular Updates and Maintenance

Regular updates and maintenance are crucial for optimal performance and accuracy in temperature control systems․ Failing to update software or maintain hardware can lead to inefficiencies and costly repairs․ Schedule routine checks to ensure all components function correctly․ This proactive approach prevents downtime and extends equipment lifespan․ Prioritizing maintenance safeguards system reliability and ensures consistent, precise temperature control over time․